Understanding Automated Labeling Machines

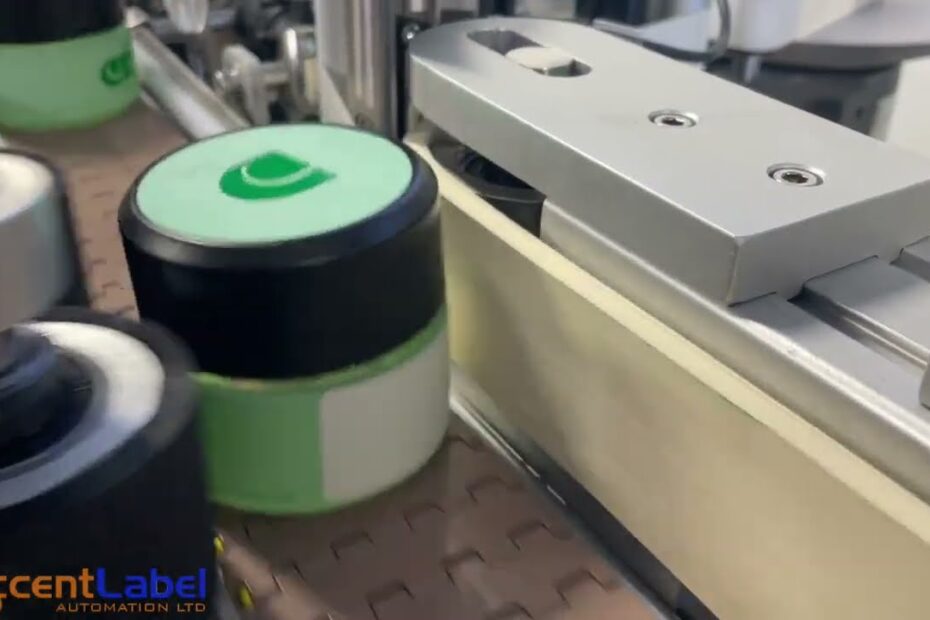

Automated labeling machines are like the unsung heroes of the production line, tirelessly slapping stickers on everything from soup cans to shampoo bottles without breaking a sweat—or accidentally gluing their own circuits together. Imagine a robot that’s part assembly worker and part over-caffeinated sticker enthusiast, using precision sensors and speedy applicators to ensure labels stick straight and true. These gadgets turn what used to be a tedious, error-prone chore into a symphony of automation, where misaligned labels become as rare as a unicorn in a factory. With their clever tech, like adjustable speeds and adaptive pressure, they handle everything from delicate glass to rugged packaging, all while making you wonder if they’re secretly judging your handwriting on those old manual labels.

One of the biggest perks of these machines is how they crank up efficiency while cutting down on human goof-ups, and here’s a fun rundown of why they’re basically the MVPs of labeling:

- They zoom through tasks at warp speed, labeling hundreds of items per minute without needing coffee breaks or snack runs.

- They eliminate wonky placements, ensuring every label looks professionally perfect—like a celebrity red-carpet appearance.

- They adapt to various materials and shapes, so whether it’s a curvy bottle or a flat box, nothing gets left out in the cold.

Benefits of Automated Labeling Machines in Industry

Automated labeling machines aren’t just fancy robots slapping stickers on boxes—they’re the unsung heroes of the production line, turning what used to be a chaotic mess into a symphony of precision that even a perfectionist squirrel would envy. Imagine ditching the days of human errors, like labels ending up sideways or missing altogether, which could make your products look like they partied too hard in the warehouse. These machines crank out labels at warp speed, boosting efficiency by up to 70% in high-volume settings, and they do it with the kind of accuracy that ensures every bottle or package is on point, saving you from those awkward customer complaints that start with “Wait, what is this?”

One of the standout perks includes a lineup of efficiency gains that keep operations humming:

- Increased speed: They label items faster than you can say “sticker shock,” handling thousands per hour without breaking a sweat.

- Enhanced accuracy: Say farewell to mislabeled mishaps that could cost a fortune in recalls.

Plus, in industries from food packaging to pharmaceuticals, these automated wonders ensure consistent results, making your workflow as smooth as a well-labeled conveyor belt rolling into peak productivity.